S55 ENGINE CRANK HUB UPGRADE: FIXING THE ACHILLES HEEL OF THE BMW S55!

The S55, BMWs mighty three litre straight six twin-turbocharged engine, as fitted to the M2 competition, M3 and M4 models is a fantastic power plant, with huge tuning potential, it does however have one major ‘flaw’ in its design, and that is the crankshaft hub/camshaft chain drive interface, which has unfortunately become a very common failure point when tuning, and the issue can even affect vehicles with a stock engine, albeit rarely

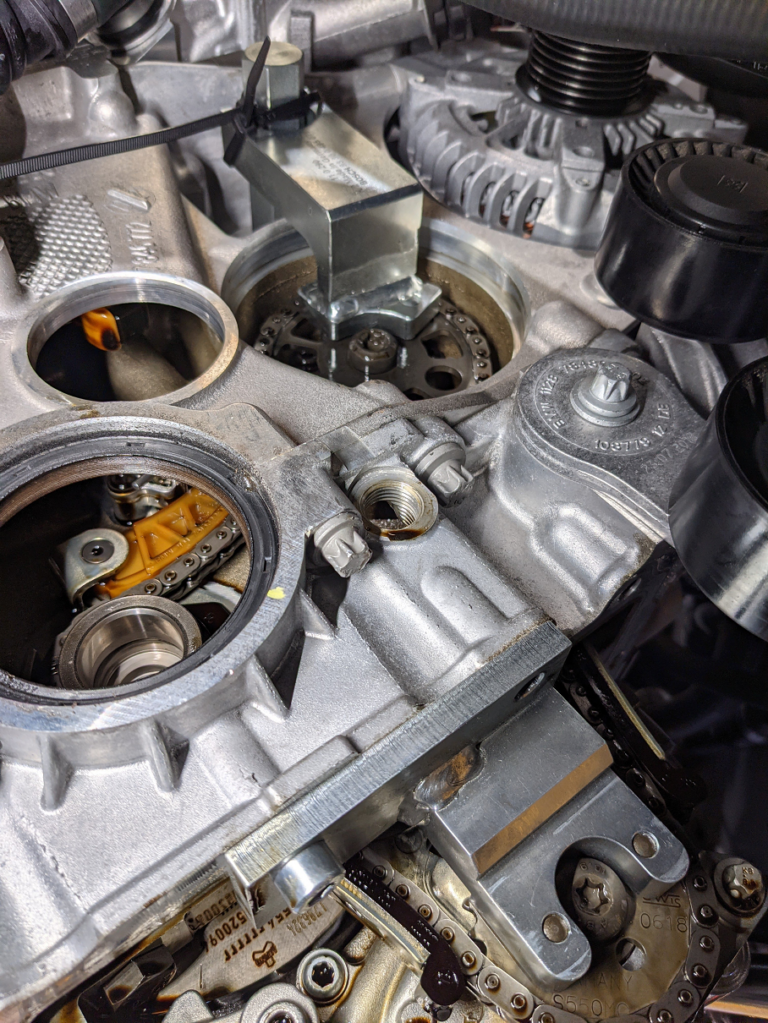

The problem can be traced directly to the method used to connect the timing chain gears to the crank pulley, as standard BMW uses a three-piece design with friction washers between the clamping surfaces, meaning the assembly is held together purely on bolt tension with no physical keyways. This makes for easy assembly, installation, and adjustment of the timing chains with regards to setting the camshaft timing, but with no physical keyway the hub can ‘slip’ under large torque demand from the engine, meaning the camshafts will no longer be synchronized to the crankshaft correctly which at best will give poor running, but at worst will result in valve to piston contact and total engine failure.

The reason this affects tuned engines is to do with the aggressive torque delivery provided by the twin-turbo setup on the S55, which can see a significant torque ‘moment’ when the boost comes in, which in turn overwhelms the friction washer and crank bolts’ ability to keep the crank hub in place, even with the bolt remaining torqued to spec. This is why we strongly recommend having the issue addressed when tuning to any power level, to avoid a potentially much larger bill further down the road

Failures

It is true to say that not all crank hub failures will lead to significant engine damage if you are lucky the slip angle of the hub will be very small and the valves will not contact the pistons, in these cases, the car will display the dreaded ‘drivetrain error’ on the dash along with timing error codes in the DME, and in some cases, the vehicle continues running in limited power mode, the fix would be to upgrade the crank hub and retime the engine, however in other cases the hub will slip far enough to allow piston to valve contact and do serious damage to the engine, requiring the engine to be removed from the vehicle, the cylinder head to be removed to have valves and guides replaced and even raises the possibility of needing replacement pistons, as you can imagine in this scenario the costs are significant! And while we are more than happy to offer a full engine rebuild service in worse-case situations, there is a solution to negate that possibility.

The Fix in more detail

There are currently two solutions available to remedy this issue, firstly a ‘capture plate’ can be installed over the standard crank hub bolt, this is designed to prevent the bolt from coming loose which would obviously cause the hub to be able to slip, but from our experience we have found the torque of the main bolt to be inconsequential in the majority of failures, and so have focused on the second solution, to replace the hub with an all new single piece design which is either pinned in place or connected to the crankshaft using a keyway, either of which are, in our opinion, far more robust than any capture plate can be, to this end we do not feel the need to fit a capture plate when installing a one piece hub design

As mentioned we offer two types of hub, one of which is pinned to the crankshaft using four dowels drilled into the end of the crank face, or a premium key way design which requires the crankshaft nose to be machined for a key way groove, we have used other units on request, but these are the options we recommend as they are simply the strongest design available, and more than worth the extra time and effort during installation to ensure crank hub slip is a thing of the past

Interested in getting your crank hub fixed? Get in contact to discuss your options…

OUR SERVICES INCLUDE

-

Following Parts Used

BMW TwinTurbo Genuine Oil

BMW Oil Filter

Sump Gasket

Rocker Cover Gasket

Sump Bolts

Cam Bolts

Crank Shaft Bolt

Oil Pump Bolt

Alloy Caps -

Professional Crank Hub installers

Here at WG Motorworks our expert technicians are highly experienced having carried out over thirty crank hub installations in the past year alone and use all genuine OEM tooling and processes alongside the highest quality standard tools when working on your vehicle to ensure the work is carried out to an exacting standard, utilising OE parts where possible and we use only the highest quality suppliers for the new upgraded crank hub, so you can be confident your vehicle will be returned to you in better than OEM spec with an engine ready to realise its full potential