F40 Gearbox & Clutch Services / Information / Repairs / Upgrades

Includes removal and installation of the gearbox and a full disassembly of the gearset, casings are cleaned thoroughly and a full inspection carried out, including careful assessment of any other potential issues, before replacing the faulty 2nd gear components with the Genuine GM repair kits. The unit is then refilled with high-quality gear oil once the rebuild process is complete.

We use only genuine GM repair kit parts, which consist of everything needed in order to resolve the problem. This kit includes new 2nd gear; synchromesh hub with 1st and 2nd triple ring synchros; a new set of bolts, and selector fork for 1st /2nd and 5th /6th gears.

Full gearbox removal is required for the repair, and we highly recommend that whilst the gearbox is out an uprated clutch is fitted at the same time.

- £1080 – Drive in drive out, while you wait service (Same Day)

All Prices include VAT, parts (as detailed above) and labour

Bearing Replacement Service – consists of replacing all 8 gearbox bearings, which include: 6th gear bearing; 4th gear output shaft bearing; both input shaft and both pinion bearings along with the differential bearings. This involves removing the complete gear set, and total disassembly of both input and output shafts/gears sets, and replacing all inner and outer races.

Casings are cleaned thoroughly and put through our Hot Wash before a full inspection is carried out, and refilled with high-quality gear oil once rebuild is complete

- £1199 – Drive in drive out, Full gearbox overhaul- gear shaft disassembly, cleaning and installation of all new gears/diff bearings and drive shaft seals.

- £799 – Gearbox supplied only

- £1699 – Bearing Replacement Service Inc 2nd Gear replacement service

All Prices include VAT, parts (as detailed above) and labour

Clutch replacement service involves gearbox removal and install, the price below is labour only, please check our online shop for current Clutch prices which can be found here.

- £480 – Drive in drive out, while you wait service (Same Day)

WG Motorworks is please to be able claim that we are one of few F40 repairers in the country. With hundreds of happy customers leaving us fantastic reviews, from local customers as well as those who come to us having travelled from far and wide! We use only the best components, Genuine GM Repair kits and OE bearings. While also using a high gear grade gearbox oil – Fuchs Titan

Our normal repair service is offered as – Drive in drive out, while you wait same day repair.

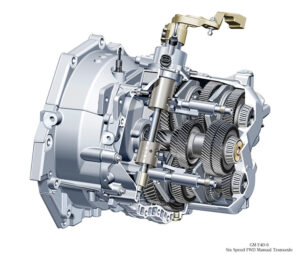

The F40 gearbox is found in many GM vehicles, including the Astra J VXR. This gearbox suffers from a few issues, starting with poor gear selections into 2nd, especially when changing from 1st gear. This will eventually lead to popping out of 2nd gear, which is when the gear is selected and clutch released with throttle (load) applied, the gear ‘pops’ out and the gearstick returns to neutral. Once this starts to happen, the only resolution is to have the gearbox repaired.

The first image below shows worn/burred engagement teeth on the synchro hub ring, and on the next image the engagement slots on the gear itself, which the synchro hub ring locks onto. This excessive wear affects the gearboxes ability to synchronise the gear speeds prior to full engagement, which in turn stops the smooth meshing of these two parts. Replacing these worn parts with a new gear will allow for correct gear speed synchronisation and meshing of the synchro ring when selecting this gear.

Repair kit includes: new 2nd gear; new synchromesh hub with 1st and 2nd triple ring synchros; a new set of bolts, and a new selector fork for 1st /2nd and 5th /6th gears.

Once the gearbox is removed, it is stripped, cleaned and meticulously inspected for any other issues, before replacing the faulty components with our repair kit.

Full gearbox removal is required for the repair, and we highly recommend that whilst the gearbox is out an uprated clutch is fitted at the same time.

Once rebuilt the gearbox is refilled with 2.5 litres of Fuchs Titan Race SRG gearbox oil. Typically we find that the manufactures do not put enough oil in the gearbox from the factory, so we refill with the correct amount, and it is important to add this to your service schedule and replace the oil annually, refilling with 2.2 Liters (0.3 will remain in the gearbox when drained) following the rebuild. Annually changing the gearbox oil using Fuchs Titan Race SRG, along with the addition of a short shifter, has led to very positive feedback from customers regarding improved overall feel and reliability of the gearbox.

Repair kit includes: new 2nd gear; synchromesh hub with 1st and 2nd triple ring synchros; a new set of bolts, and selector fork for 1st /2nd and 5th /6th gears.

Once the gearbox is removed, it is stripped, cleaned and carefully inspected for any other issues, before replacing the faulty components with our repair kit.

Once rebuilt the gearbox is refilled with 2.5 litres of Fuchs Titan Race SRG gearbox oil. Typically, the manufactures do not put enough oil in out of the factory, so we refill with the correct amount, and it is important to refill annually using 2.2 Liters (0.3 will remain in the gearbox) following the rebuild. Annually changing the gearbox oil using Fuchs Titan Race SRG, along with the addition of a short shifter, has led to very positive feedback from customers regarding improved overall feel of the gearbox.

Although the manufactures quote 295lbft, we often see standard cars putting out around 320-340lbft. The quick spooling twin scroll turbo producing higher than expected torque and long gearing often lead to clutch slip in higher gears.

‘What is Clutch slip?’ Clutch slip is when the torque output of the engine is not being fully transferred across to the transmission via the clutch friction plate, resulting in engine RPM rising without a corresponding rise in vehicle speed. This is most often noticed by the rev counter needle shooting up and ‘hanging’ whilst the wheel speed catches up with the engine. This often occurs at peak torque between 2500-3500rpm, and is more likely to happen in higher gears and on inclines due to the increased torque ‘moment’ that occurs in these scenarios.

This is caused by the clutch cover being unable to retain sufficient clamping force between the clutch friction plate and flywheel.

Fix

We have teamed up with clutch experts Helix Autosport, who have exclusively produced our heavy-duty clutch covers, which resolve any slip issues by increasing the clamping force onto the flywheel. There are 3 options, first being an uprated Cover and plate to suit the stock dual mass flywheel (DMF). For those going even further with power, there is also a sprung uprated organic friction plate available and 6 paddle options which pairs to a solid mass flywheel (SMF) for the ultimate setup when chasing maximum engine output. Click here for prices